Mig Welding Wire

Applications

Welding of mild steel and 490MPa high tensile strength steel for automobiles, rolling stock, electric appliances, machinery, air conditioners, light gauge steel, pipes, steel frames, bridges and ships.

Characteristics

Strong Weld is a gas metal arc welding wire to be used with CO2 shield gas. Arc is stable, spatters are few and weldability is excellent even with low current under 200A. Welding of thin plates in all positions. especially in vertical downward position, is easy. Also, it shows better weldability in high speed welding of thin plates with currents of less than 300A than wires of other types. Also with Ar+CO: mixture gas, arc is stable, spatters are few and bead is beautiful in a wide welding current range.

Guidelines for Usage

1. In vertical downward welding, wire should be held at an angle slightly above horizontal.

2. Optimum arc voltage should be selected in accordance with welding current to maintain stable dip transfer mode. If voltage is too high or too low, dip transfer frequency will decrease.

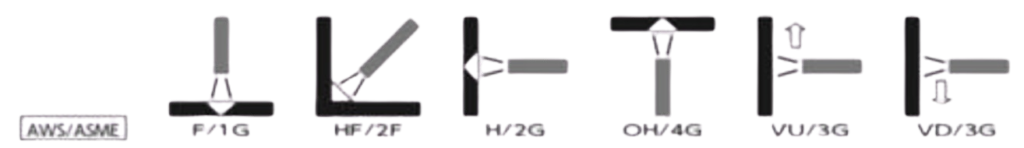

Welding Position

Typical chemical composition of wire (%)

| C | Si | Mn | P | S |

|---|---|---|---|---|

| 0.07 | 0.86 | 1.53 | 0.012 | 0.007 |

Typical Mechanical Properties of Weld Metal

| Shield Gas | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Charpy 2V-notch at 0°C (J) |

|---|---|---|---|---|

| CO2 | 450 | 550 | 27 | 120 |

| Ar+20%CO2 | 480 | 590 | 27 | 130 |

Sizes & Recommended Current Range (DC +)

| Diameter (mm) | 0.9 | 1.0 | 1.2 | 1.4 |

|---|---|---|---|---|

| F, H-Fil | 70~200 | 70~250 | 80~350 | 250~550 |

| H | 70~140 | 70~160 | 80~180 | — |

| OH | 70~100 | 70~110 | — | — |

| V-up | 70~140 | 70~160 | 80~240 | — |

| V-down | 70~200 | 70~220 | 80~240 | — |