Welding Electrodes

Welding Electrodes

Durable welding electrodes built for strength and adaptability in various welding positions.

- Types: E6013.

- Diameters: 2.5mm, 3.2mm, 4.0mm.

- Packaged for bulk orders.

Welding Electrode

AWS A5.1 E6013

Characteristics and Application

AWS A5.1 E6013, Welding Electrode is designed for high efficiency welding with thin flux coating. It features good slag release, shallow penetration, less spatters, and smooth bead appearance. It is suitable for welding application of vehicles, steel sheets and other light structures.

Typical chemical Composition of Weld Metal (%)

| Element | C | Mn | Si | P | S |

|---|---|---|---|---|---|

| Composition (%) | 0.07 | 0.30 | 0.25 | 0.025 | 0.015 |

Typical Mechanical Properties of Weld Metal

| Property | Value |

|---|---|

| Yield Strength | 450 MPa |

| Tensile Strength | 520 MPa |

| Elongation | 25% |

| Charpy V-Notch | -0 °C 50J |

Notes on usage:

1. Be sure to clean up the contamination on the base metal to reduce the cause of welding defect.

2. It is highly recommended to dry the electrodes at 80-100°C for 30-60 minutes before using.

3. Apply proper currents to prevent X-Ray and mechanical properties from being worse.

4. Keep the product dry, while it is stored or delivered.

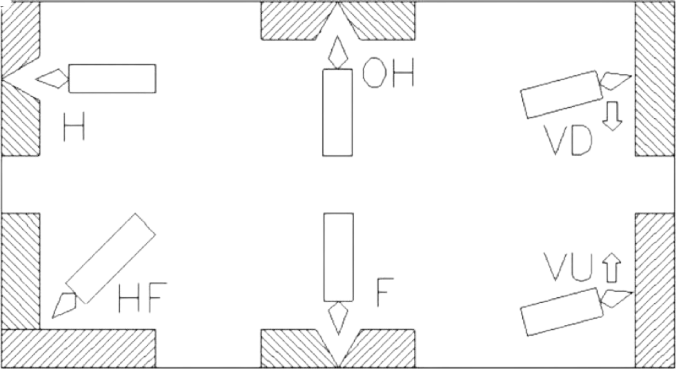

Welding Positions